Recently, Chairman Lin Guang of Guangdong Huihuang Environmental Protection Technology Co., Ltd. visited the Secretariat of the Special Committee and had a discussion and exchange with Alan Leong, Deputy Secretary General of the China Plastics Association and Executive Vice President and Secretary General of the China Plastics Association Plastic Home Products Special Committee.

During the meeting, Director Lin introduced the brilliant achievements of environmental protection innovation research and development and the concept of enterprise development. Guangdong Huihuang Environmental Protection Technology Co., Ltd. is a professional enterprise that provides solutions for sustainable ecology in the environmental packaging industry. On the track of "replacing plastic with paper" since 2020, we have persisted in continuous innovation and research and development, adhering to the belief of "sustainable operation, non-toxic and harmless, and win-win". Through continuous research and development experiments and setbacks, we have faced and corrected mistakes, and finally launched a true solution of "making plastic with paper".

Guangdong Huihuang Environmental Protection Technology Co., Ltd. successfully launched a cellulose plasticization method using pulp as the material in 2023, which combines high-tech and adopts a completely different plasticization method from traditional PE, polyethylene, PP, polypropylene, etc., endowing pulp fibers with plastic properties while retaining the environmental characteristics of pulp, such as compostability, degradability, and recyclability. Therefore, it truly realizes the concept of "making plastic with paper" and practices environmental protection. Huihuang Environmental Protection Technology Company adheres to building a sustainable ecology for the environmental packaging industry, and insists on making sustainable development of the social environment its corporate development creed, responding to the government's policy requirements for a circular economy.

Executive Vice President and Secretary General of the Special Committee, Alan Leong, briefly introduced the service purpose and development concept of the committee, and stated that in the new ecological and environmental protection pattern, enterprises actively innovate, transform and upgrade, and sustainable green and environmental protection development is an inevitable trend in the development of the plastic home goods industry.

Subsequently, Chairman Lin Guang accompanied Executive Vice Chairman and Secretary General of the Special Committee, Alan Leong, to visit the new factory under construction of Guangdong Huihuang Environmental Protection Technology Co., Ltd.

The special committee is a platform for gathering connections, building platforms, sharing business opportunities, and developing together. The special committee has built communication bridges between enterprises, between enterprises and consumers, upstream and downstream industrial chains, experts, universities, and relevant government departments, promoting the formation of a collaborative innovation and mutually beneficial cooperation atmosphere in the plastic home goods industry, laying the foundation for the special committee to accurately serve member enterprises and promote win-win cooperation among enterprises.

Glorious Environmental Protection Technology Factory Map

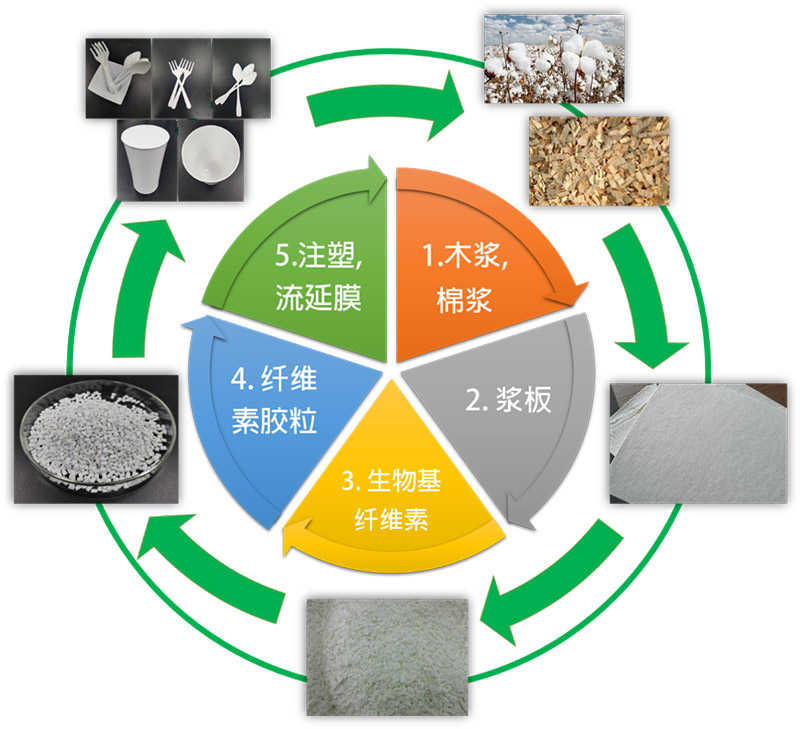

Huihuang Environmental Protection [Paper to Plastic] Development Process

Since the invention of plastic in 1922, it has opened up a major step forward in the quality and convenience of human life. In the torrent of time, it continues to emit light and heat, bringing convenience to people's lives. However, it also gradually forms what is called plastic waste, which will be retained for decades or even centuries and flow into the ocean. And the oceans on Earth are the origin of all life, yet they have been silently enduring the harm caused by plastic. In the eyes of Chairman Lin Guang, who was born into a printing family, this is a major problem that needs to be solved in people's livelihoods. He has been learning relevant professional knowledge from his father since childhood, so he has devoted a certain degree of expertise and passion to paper. On the path of environmental protection, he has developed his own beliefs and persistence. On the track of "replacing plastic with paper" that began in 2020, he insists on continuous innovation and research and development, adheres to the concept of "sustainable operation, non-toxic and harmless, and win-win", faces mistakes and corrects them in the face of continuous research and development failures, and finally launches a true solution "making plastic with paper".

In 2023, Guangdong Huihuang Environmental Protection Technology Co., Ltd. successfully launched a cellulose plasticization method using pulp as the material, combined with high-tech technology. It adopts a completely different plasticization method from traditional PE, polyethylene, PP, polypropylene, etc., endowing pulp fibers with plastic properties while also retaining the environmental characteristics of pulp, such as compostability, degradability, and recyclability. Therefore, it truly achieves the goal of "making plastic from paper".

Chairman Lin Guang of Huihuang Environmental Protection proposed the concept of "making plastic with paper", which has two new understandings:

The word "plastic" in the first point "made from paper" does not mean plastic, but rather "plasticization" in chemical reactions. Simply put, it means giving pulp the same characteristics as plastic, which is a new understanding.

The second point of "making plastic from paper" is not the pulp molding in today's society, but the successful conversion of pulp fibers into pellets, also known as plastic rice, which can be compared to current plastic pellet processes such as injection molding machines, tape casting machines, extruders, blown film machines, etc.

Huihuang Environmental Protection has launched the HEECO series of pulp pellets in 2023, currently available in models HH-200-I HH-200-R、HH-200-C、HH-288-I、HH-288-R。

HEECO Pulp Particle Process Diagram

Products made of granules

Official Account